WHY US

@ We are very professional for investment castings making.

@ Technology from Taiwan. Casting Parts with very good consistence and beautiful finish.

@ Spectrometer Inspecting for each material batch to ensure correct material to be used.

@ Annealing Treatment to ensure consistent Micro-structure and not deform for ever.

@ If need, some parts will go into Shape Correcting process to ensure consistent shape, dimensions.

Other Statements: Why shape/dimension Rectification is necessary for castings

Not like machined parts, investment castings will deform in varying degree during production.

Usually, it is the biggest problem for this kinds of parts.

Several main reasons as below:-

@ Wax mold deformation (one main reason; wax is SOFT)

@ When casting process, during cooling down, SHRINKAGE will lead to deformation in different position/direction especially for those Asymmetrical part.

@ Part surface Shot Blasting also will lead deformation a little bit.

@ After Annealing Heat Treatment, Deformation also might happen after this process

@ We are very professional for investment castings making.

@ Technology from Taiwan. Casting Parts with very good consistence and beautiful finish.

@ Spectrometer Inspecting for each material batch to ensure correct material to be used.

@ Annealing Treatment to ensure consistent Micro-structure and not deform for ever.

@ If need, some parts will go into Shape Correcting process to ensure consistent shape, dimensions.

Other Statements: Why shape/dimension Rectification is necessary for castings

Not like machined parts, investment castings will deform in varying degree during production.

Usually, it is the biggest problem for this kinds of parts.

Several main reasons as below:-

@ Wax mold deformation (one main reason; wax is SOFT)

@ When casting process, during cooling down, SHRINKAGE will lead to deformation in different position/direction especially for those Asymmetrical part.

@ Part surface Shot Blasting also will lead deformation a little bit.

@ After Annealing Heat Treatment, Deformation also might happen after this process

| Investment Casting Spec.: Quick Details | ||||||||

| Material | Stainless Steel: CF8, CF8M, SUS 304, 304L, 316, 316L, etc. Carbon Steel: Low/medium/high Carbon Steel, G35, G45, WCB/A/C, etc. Alloy steel: Cr/Ni/Mo/V Series | |||||||

| Process | Lost Wax Casting + CNC machining (when applicable) | |||||||

| Casting roughness | Ra1.6-3.2 | |||||||

| Machining roughness | Ra0.8-1.6 | |||||||

| Casting Weight | 0.005-50kg | |||||||

| Surface Treatment | Shot/Sand Blasting, Polishing; Primer Painting, Powder Coating; Anodizing, Surface Passivating, ED-Coating, Cr/Ni Plating | |||||||

| Heat Treatment | Annealing, Normalizing, Hardening, Tempering, Case hardening.... | |||||||

| Quality Assurance | ||||||||

| IQC | Incoming Quality Control: for raw material. | |||||||

| IPQC | In Process Quality Control: * Spectrometer Checking for Each Over; * Routing inspection during mass production | |||||||

| FQC | Final quality Control: Checking the goods after they are finished. | |||||||

| OQC | Outgoing Quality Control: Prior to shipment. | |||||||

| Main Inspecting Tools & Equipments | ||||||||

| Spectrometer | Imported from Germany, for Mat'l & process checking for each oven. | |||||||

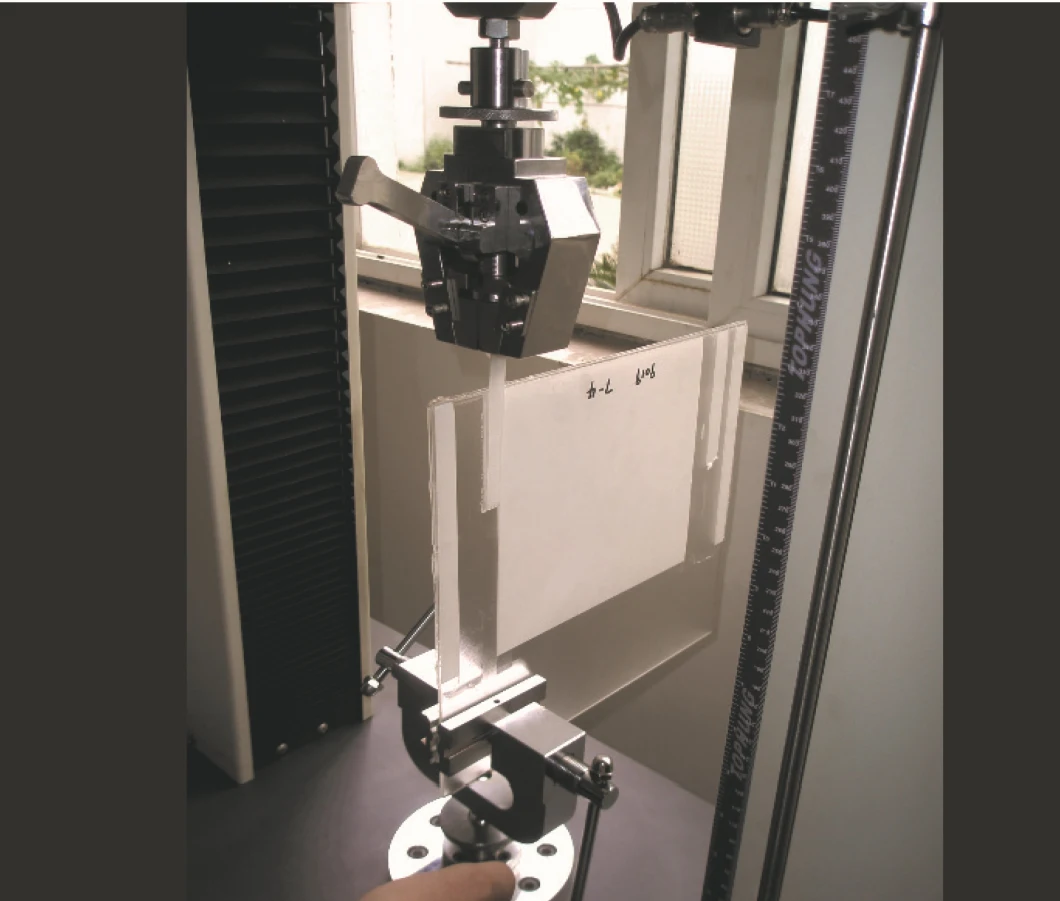

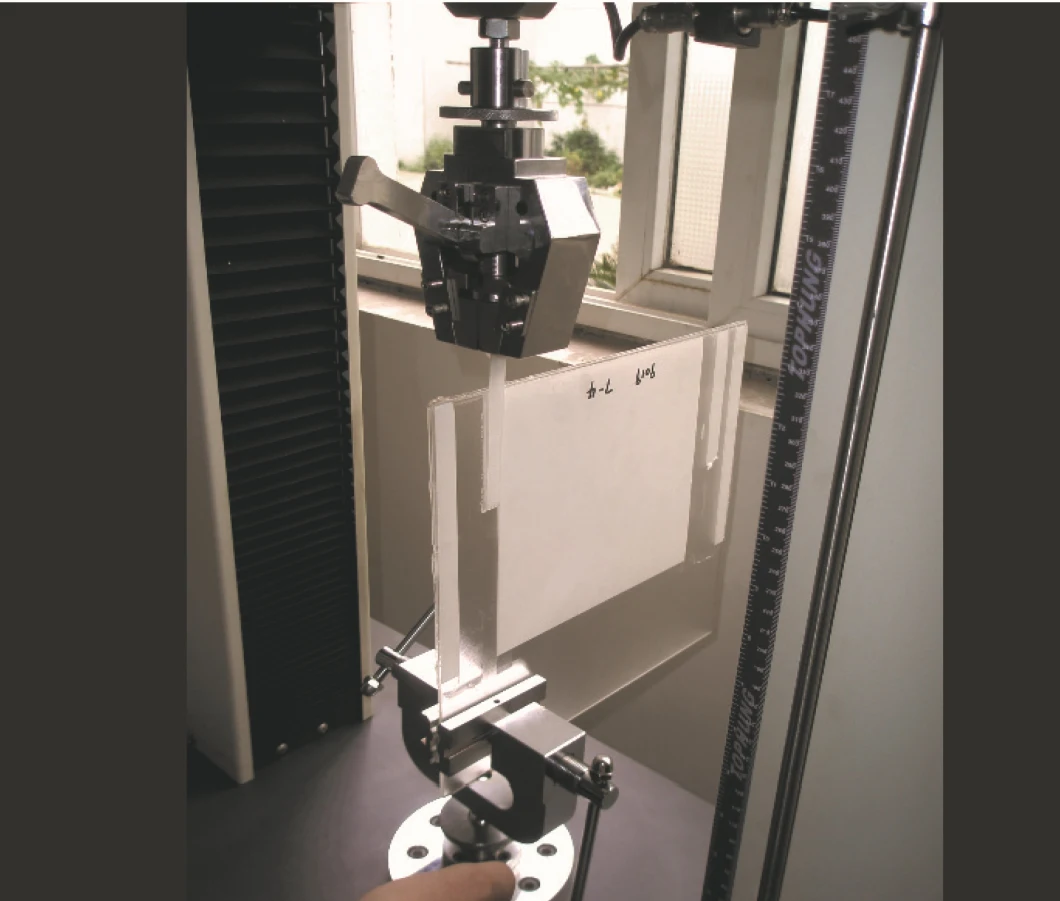

| Tensile Strongth Checking Machine | for parts with mechanical features requirements. | |||||||

| Sclerometer | for parts with heat treatment and hardness requirements. | |||||||

| Salt Spray Tester | for parts with Plating or Coating finish. | |||||||

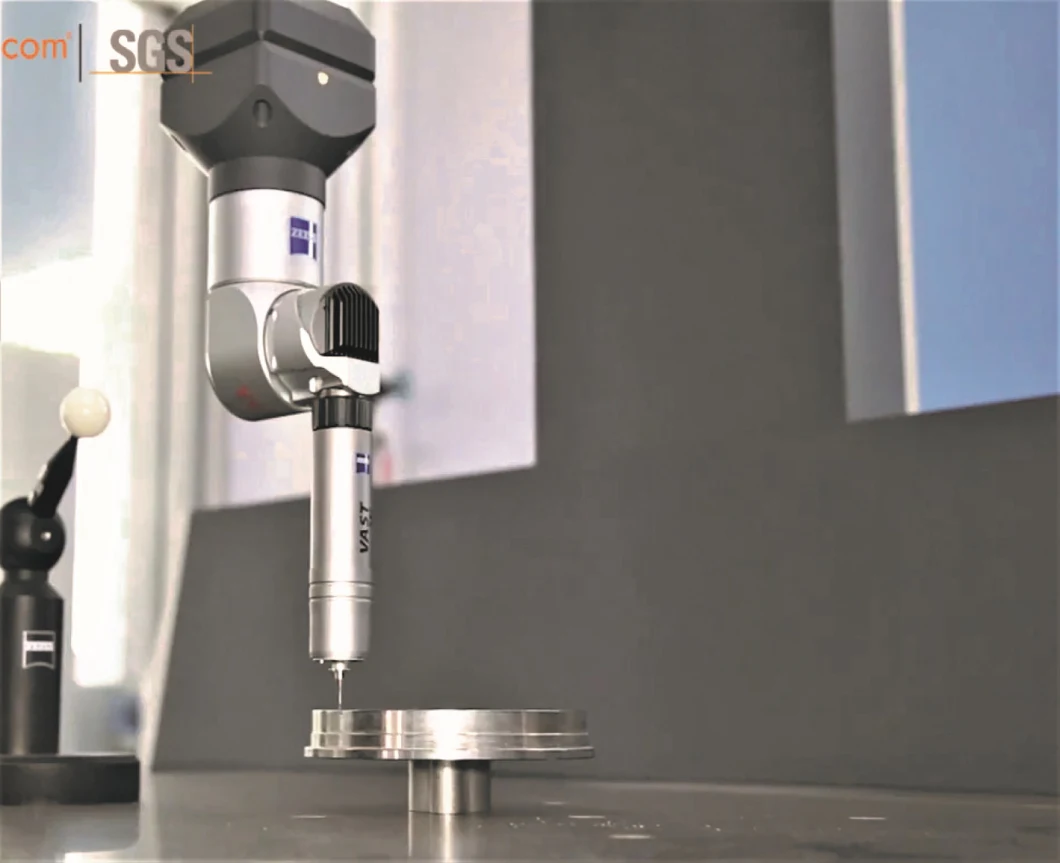

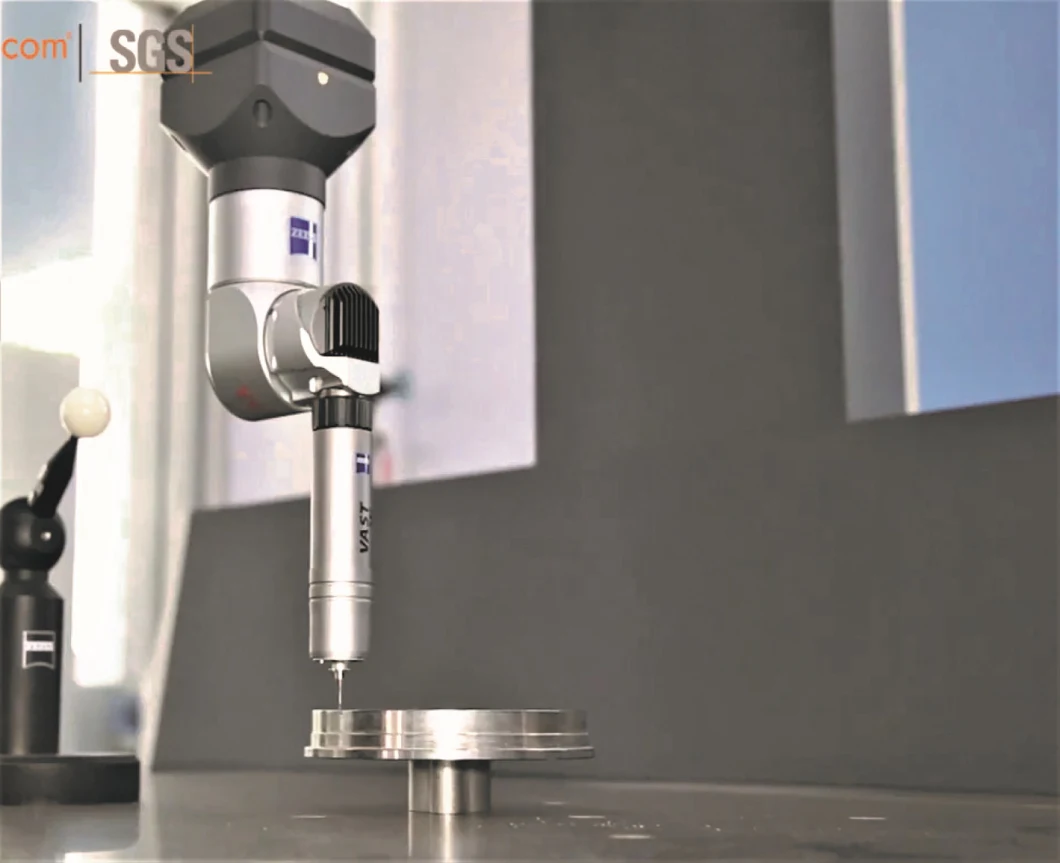

| CMM | Dims checking for parts with complex structure. | |||||||